FASTSTOCK™: LOCAL

INVENTORY MANAGEMENT

FASTStock™: Simplify

Class-c spend typically represents around 80% of the parts purchased by an organization but only 20% of the overall product cost. Translation: a lot of processing and energy goes into managing low-value parts. Moreover, the complexity of the spend often results in inventory imbalances – either too much (tying up working capital) or too little (directly impacting production). However, a disorganized and poorly managed inventory management program can result in the $0.10 item costing you thousands.

If you’re looking to simplify and improve your class-c supply chain, Fastenal is ready to help with a combination of technology, service, and logistics.

Offloading Burdens. Introducing Efficiencies.

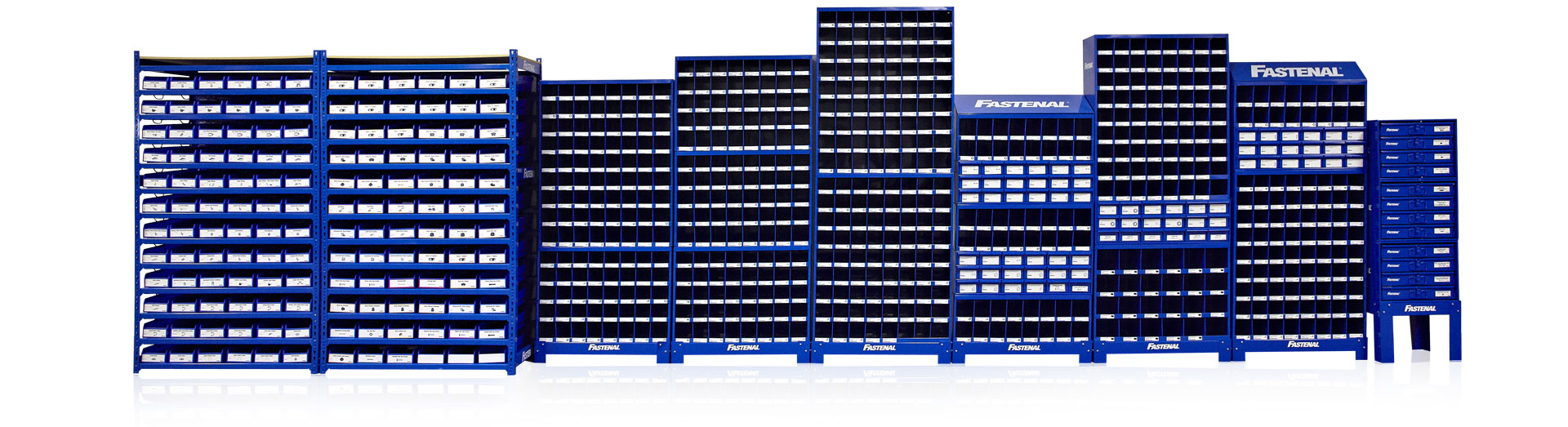

1 Organizing parts into digital planograms – enabling us to illuminate data surrounding each part (what it is, where it’s located, the min-max levels, and when we’re servicing it.)

2 Clearly Labeling Each Location – providing product images and detailed descriptions to make products easy to identify.

3 Managing Your Parts on a Regular Service Schedule – leveraging our local presence to provide in-market buffer stock and consistent service from a representative who understands your business

4 Utilizing Technology to Elevate Our Service – embracing mobility and other solutions to make our service more efficient, accurate, and transparent.

GREATER VISIBILITY AND LESS

RISK IN THE SUPPLY CHAIN

A Total Supply Chain Solution

Global Sourcing

Establishing control early in the supply chain to navigate risk and ensure continuity.

Last-Mile Logistics

Running consistent regional truck routes to maintain your cycle stock and expedite unplanned needs.

In-Market Inventory

Immediately-available buffer stock in our local branches backed by safety stock in our regional hubs.

Local Service

A dedicated, accountable team that understands your business and will adapt its service to meet your needs.

24/7 Visibility

Utilize the FAST 360º tool to analyze spend dynamics, measure cost savings, and view on-hand inventory by location, down to the individual bin position.

What Are the Opportunities for Your Business?

Decrease Spend

Through vendor consolidation and efficient category management.

Improve Working Capital

We stock your inventory needs locally so you don’t have to.

Reduced Freight Expenses

Through careful inventory planning and utilization of our transportation fleet.

Increase Productivity

By unlocking production and procurement energy for strategic activities.

Solutions To Simplify Your Supply Chain

When we talk to businesses around the world about inventory, we hear some common themes. They want less of it in their facilities, but with less risk of running out. They want fewer touches, but also more visibility. And above all, they want to reduce their total cost of ownership, unlocking resources to invest in their fundamental purpose. Through our FMI Technology® program, we help organizations achieve these common goals, driving cost, waste, and complexity out of the supply chain to do more of what they do best.